Quantity takeoffs and Cost estimation

Quantity takeoffs and Cost estimation:

Quantity takeoff is a critical process in the construction industry that involves the detailed measurement and calculation of materials, labor, and equipment required for a construction project. This process forms the foundation of accurate project planning and budgeting. Here’s how it works:

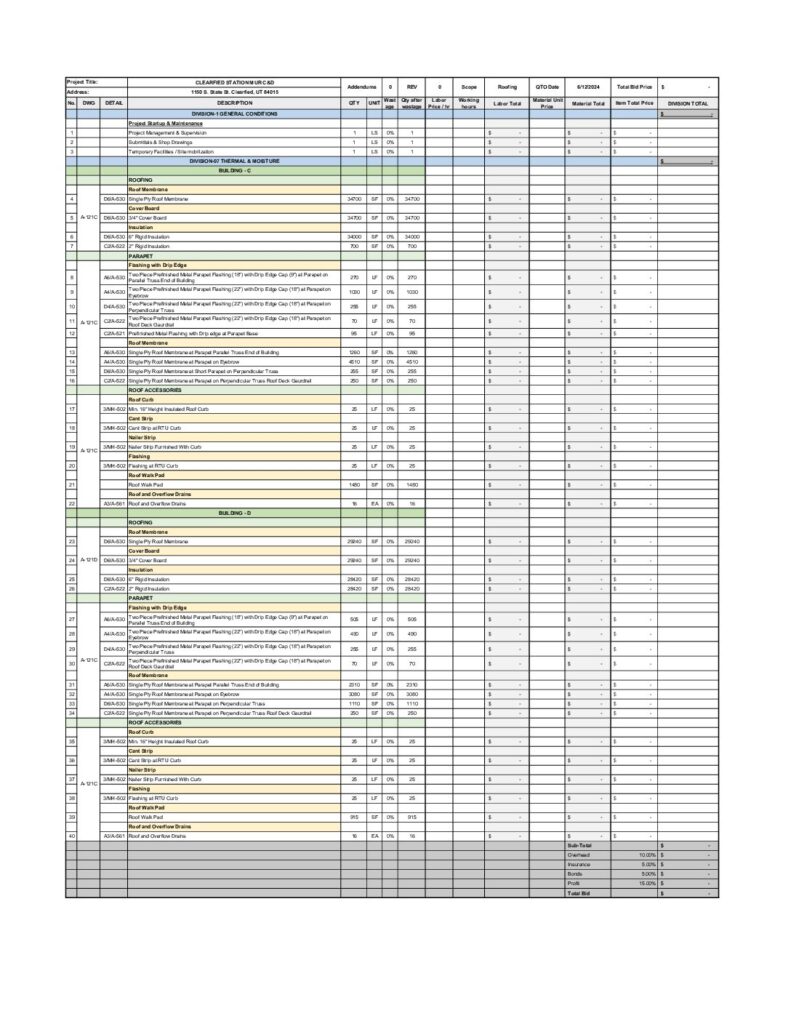

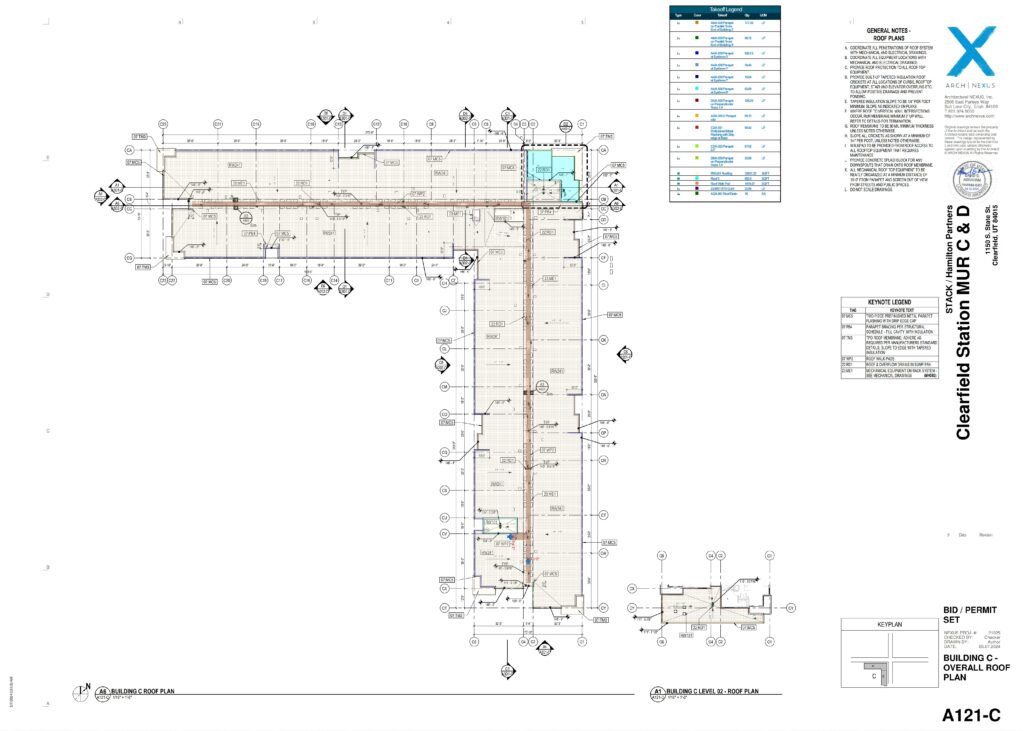

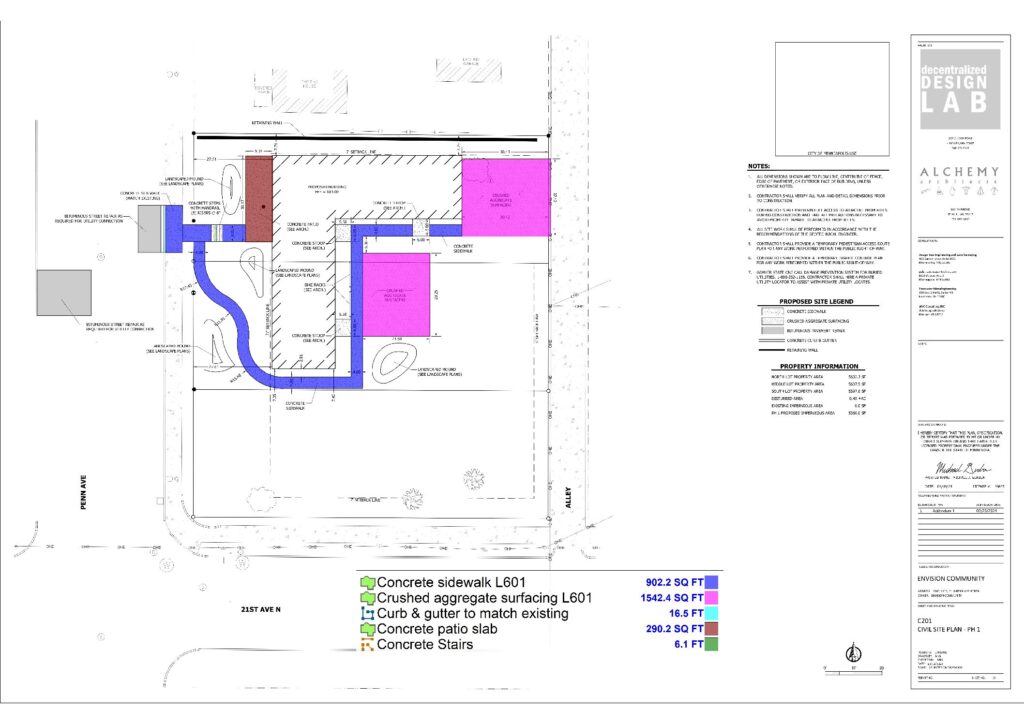

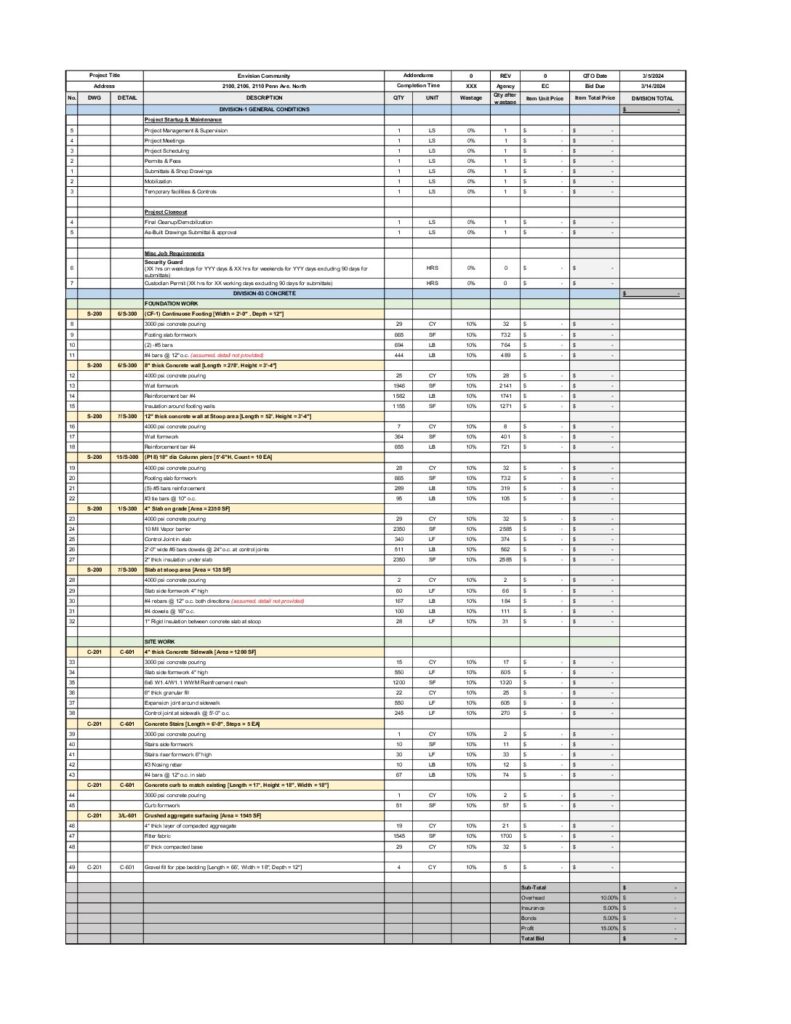

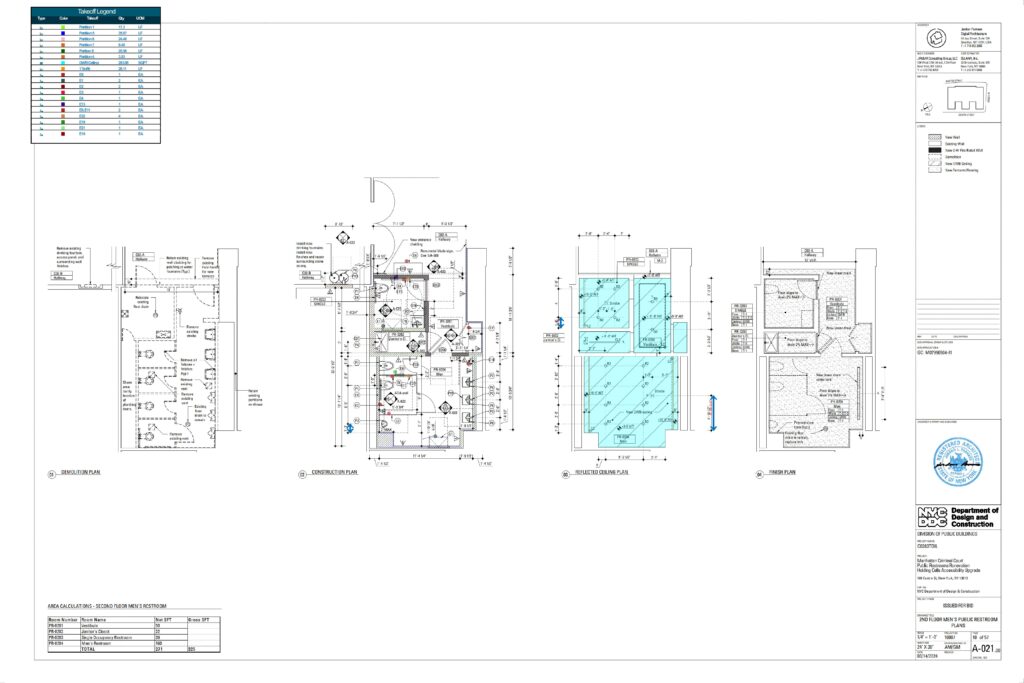

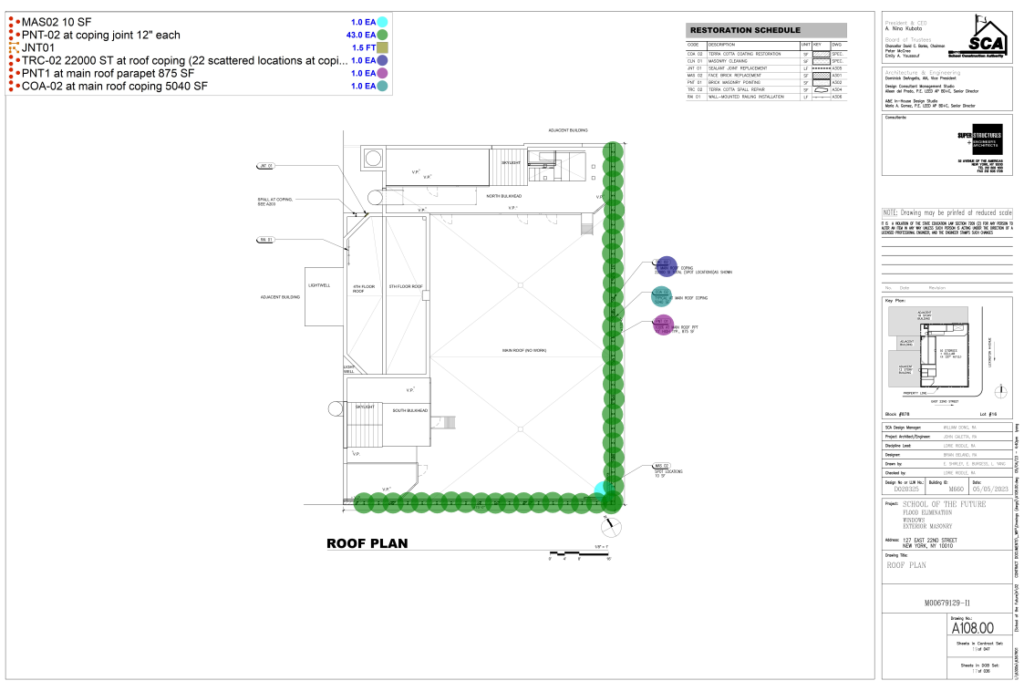

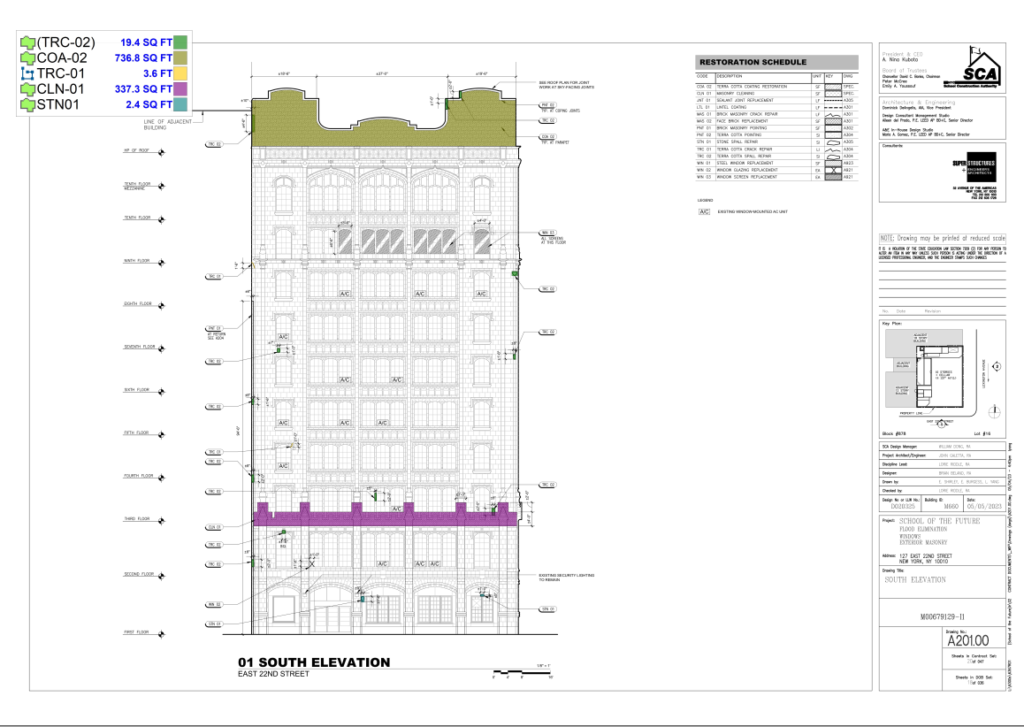

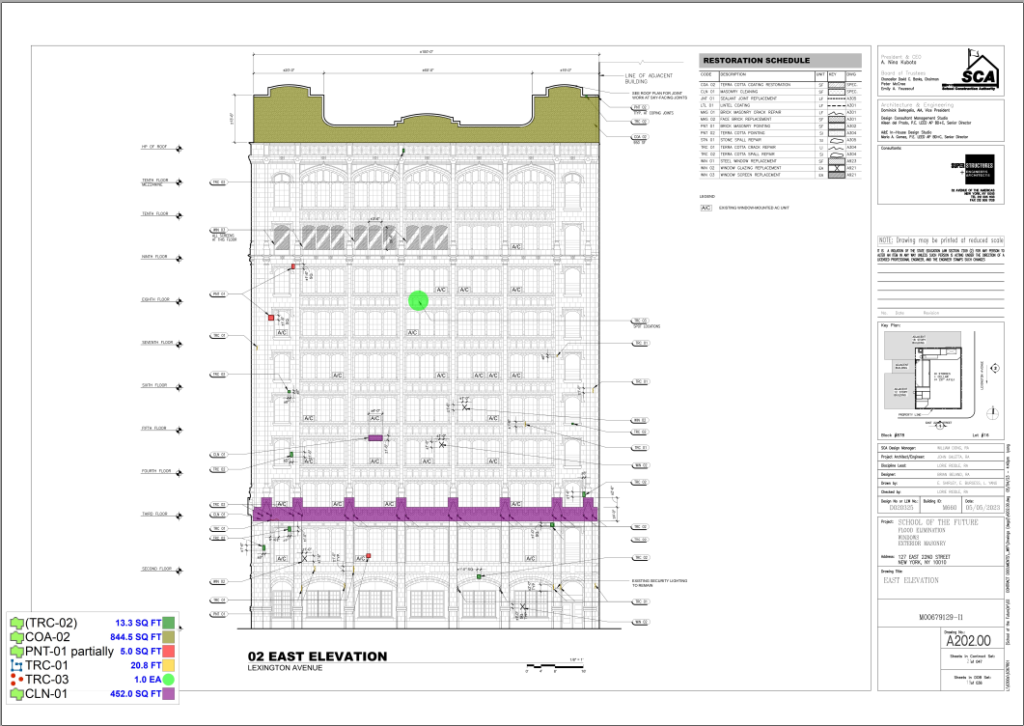

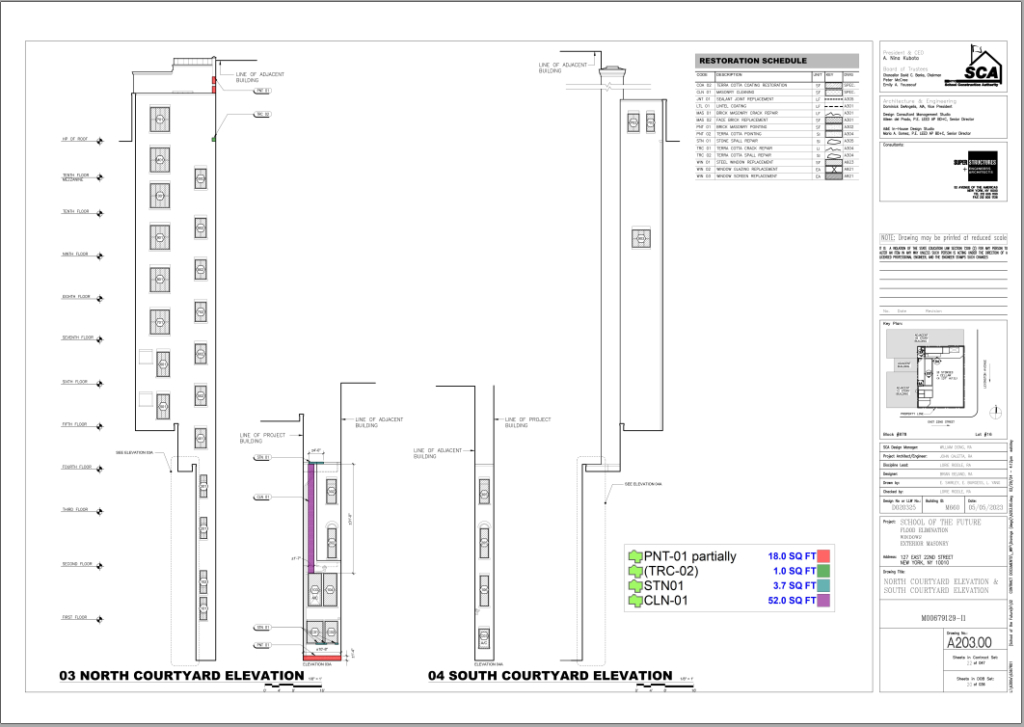

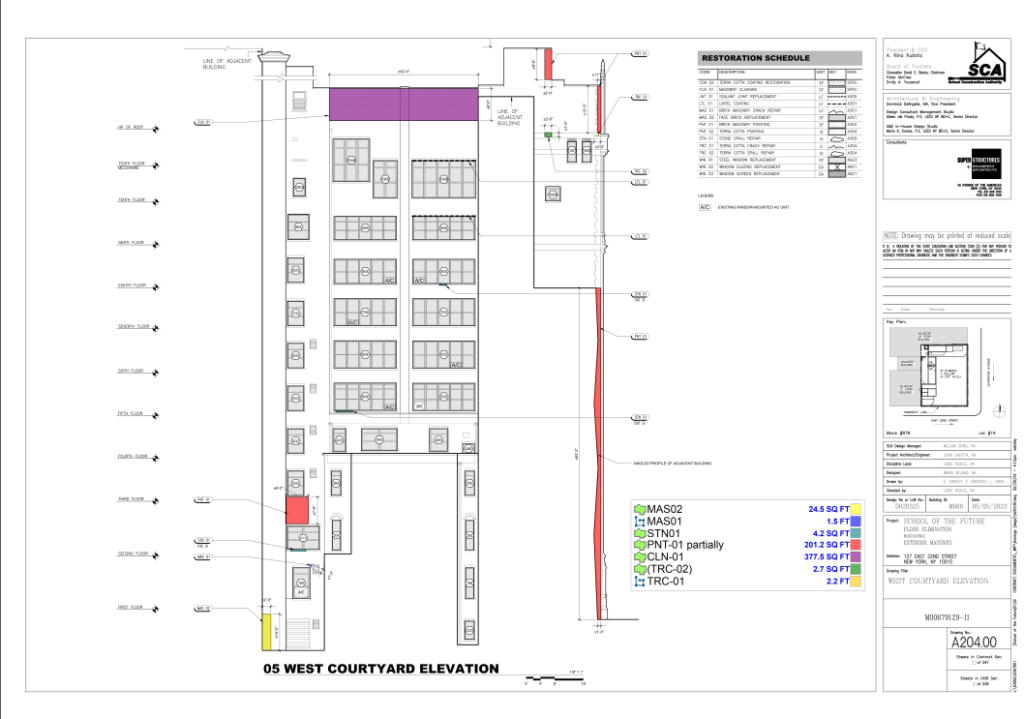

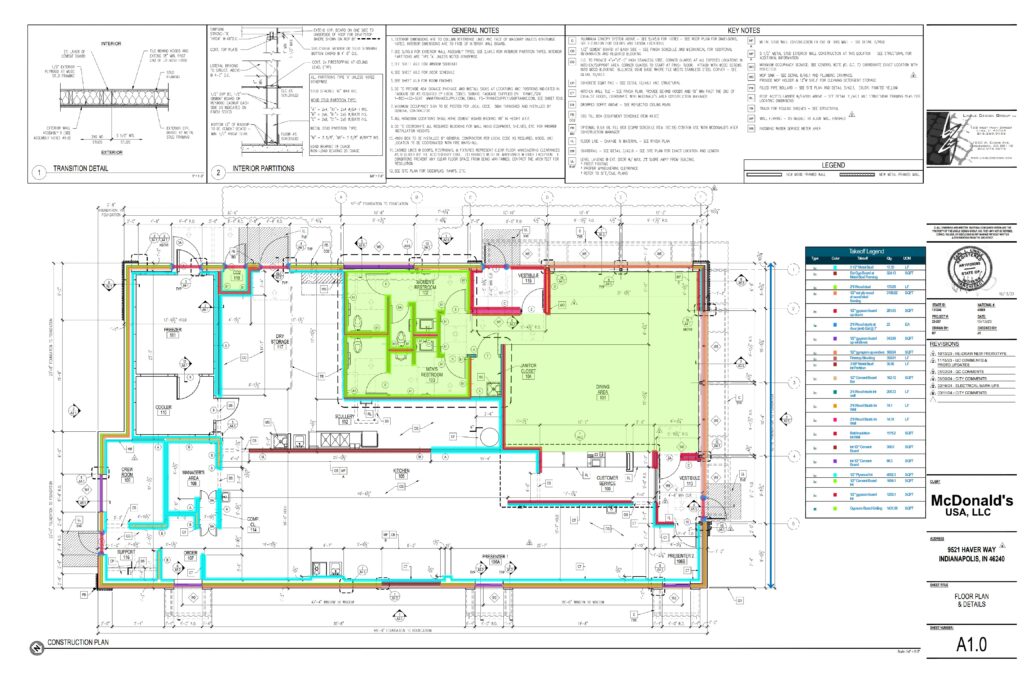

Analyzing Project Documents:

The process begins with a thorough review of project drawings, blueprints, and specifications. These documents provide the necessary details to determine the scope and scale of the project.

Quantity takeoffs and Cost estimation:

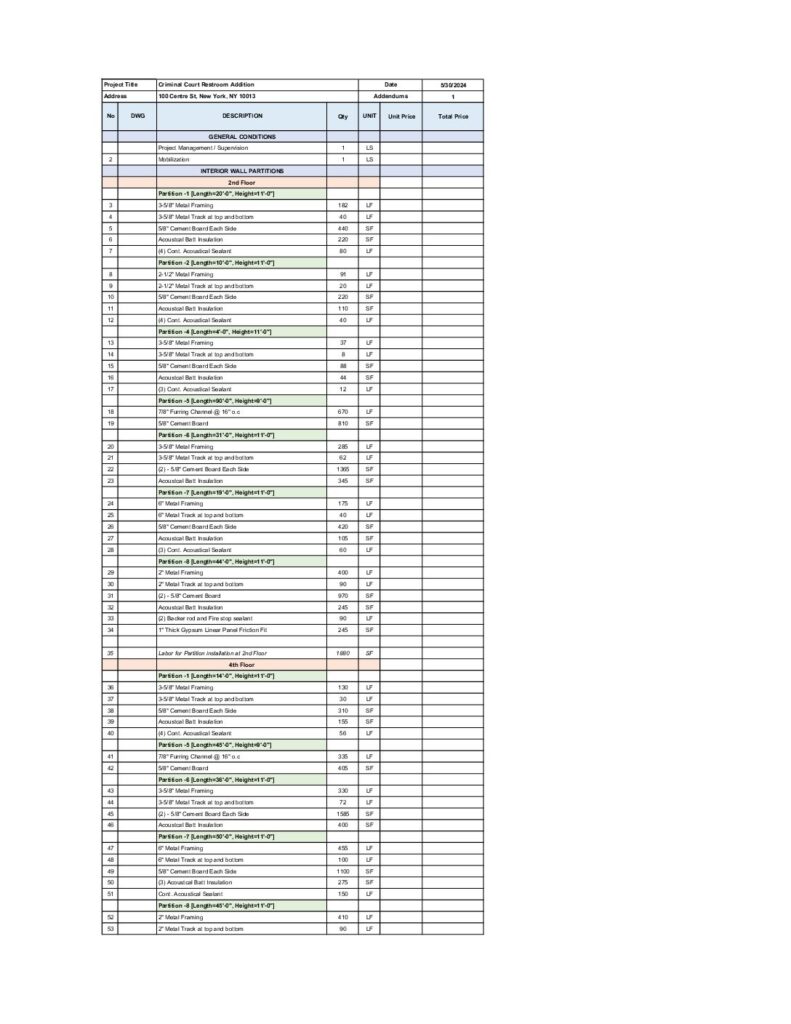

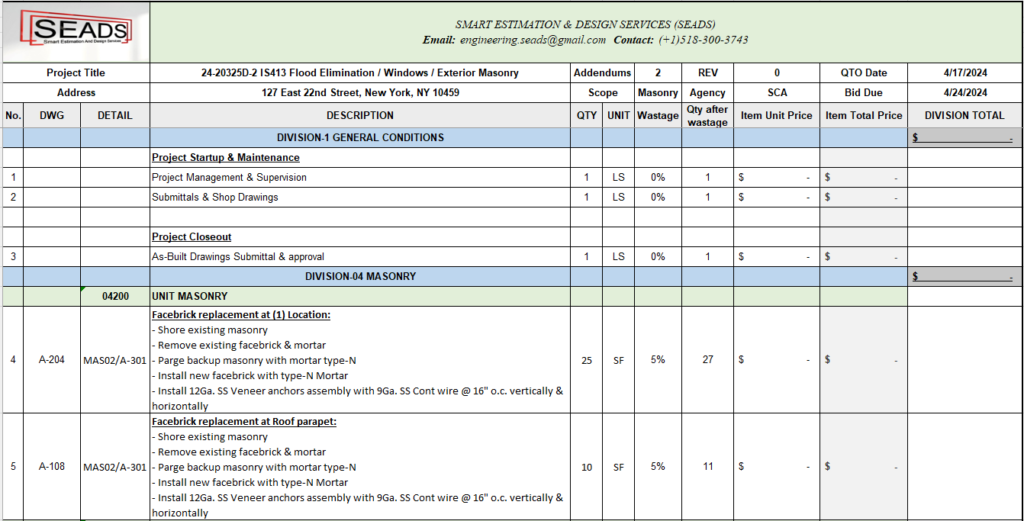

Using specialized software and tools, every element of the project is measured and counted. This includes materials such as concrete, steel, lumber, and fixtures, as well as labor hours and equipment needs.

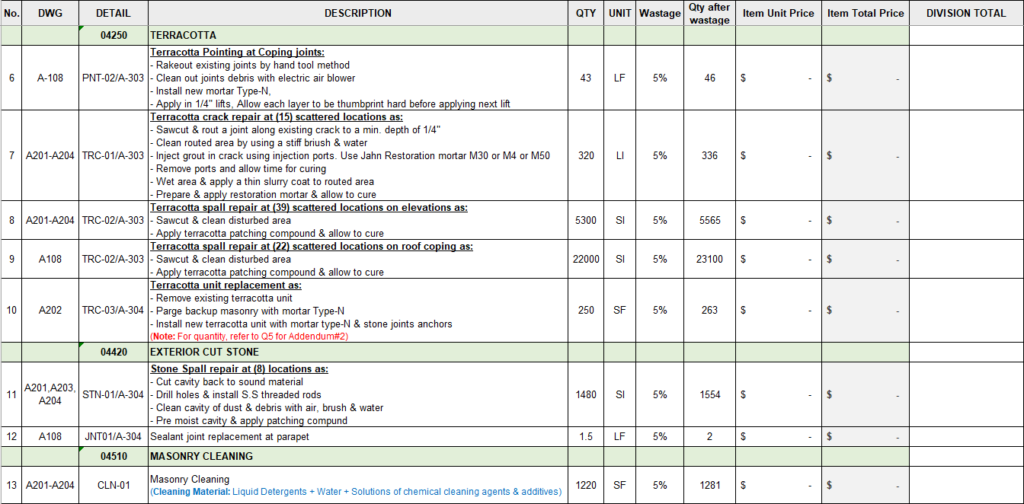

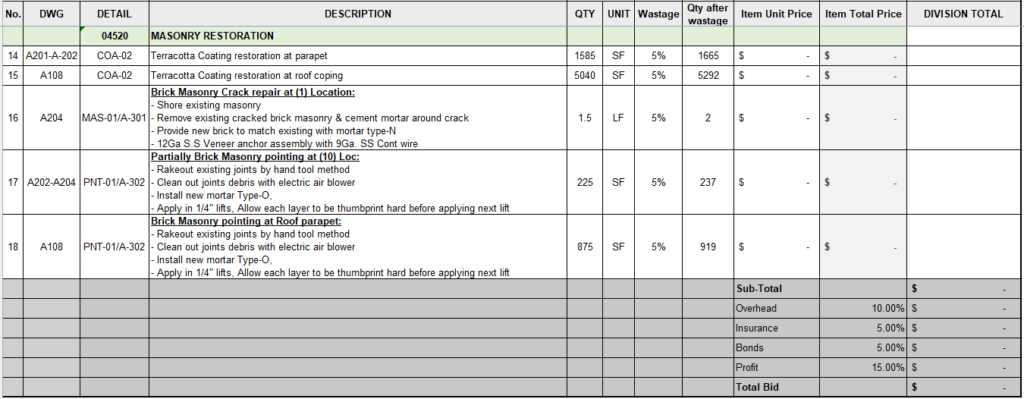

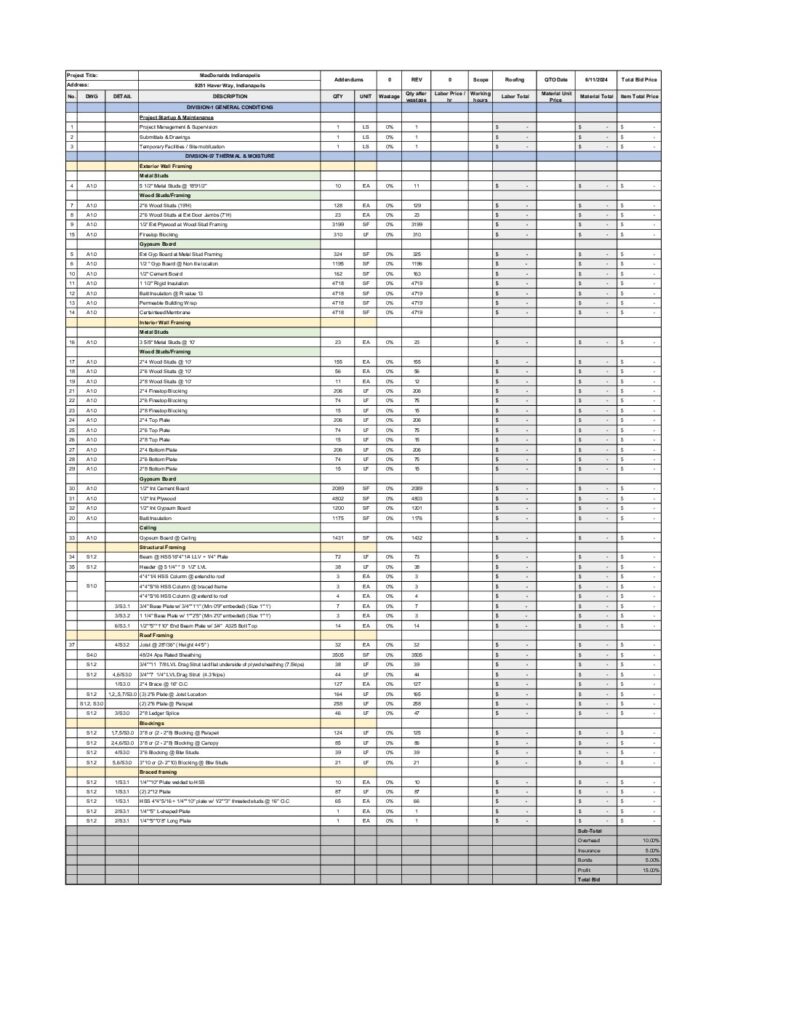

Detailed Breakdown:

The measurements and counts are compiled into a comprehensive list, known as the quantity takeoff report. This report includes detailed quantities of each material and resource needed for the project, categorized by type and phase of construction.

Accuracy and Precision:

The accuracy of quantity takeoffs is paramount, as even small errors can lead to significant cost overruns and delays. Advanced software and experienced estimators ensure that the data is precise and reliable.

Estimation Services

Estimation services go a step further by converting the quantity takeoff data into a detailed cost estimate. This process involves:

Cost Analysis:

Estimators analyze current market prices for materials, labor rates, and equipment costs. They also consider historical data and trends to predict future price fluctuations.

Comprehensive Cost Breakdown:

The cost estimate includes every aspect of the project, from materials and labor to overhead costs and contingencies. This ensures a complete and realistic financial picture of the project.

Project Budgeting:

The detailed cost estimate helps in creating a budget for the project. This budget is crucial for securing financing, planning resources, and managing cash flow throughout the construction process.

Risk Management:

Estimators identify potential risks and uncertainties that could impact costs, such as supply chain issues or regulatory changes. They include contingencies in the estimate to mitigate these risks.

Informed Decision-Making:

Accurate cost estimates enable project owners, contractors, and stakeholders to make informed decisions about project feasibility, design adjustments, and resource allocation.

Benefits of Quantity Takeoff and Estimation Services Cost Efficiency:

By accurately predicting the quantities and costs, these services help in avoiding over-purchasing or underestimating resources, leading to significant cost savings.

Time Management:

Detailed planning and accurate budgeting ensure that projects stay on schedule, avoiding delays and costly overruns.

Risk Reduction: Comprehensive cost analysis and contingency planning reduce the risks associated with price changes, supply shortages, and unforeseen issues.

Improved Communication:

Clear and detailed reports facilitate better communication among project stakeholders, ensuring everyone is on the same page.

Enhanced Project Planning:

With precise data on materials and costs, project managers can plan more effectively, allocating resources efficiently and setting realistic timelines.

By leveraging quantity takeoff and estimation services, construction projects can achieve higher levels of efficiency, accuracy, and financial control, leading to successful project outcomes.

Transforming Your Vision into Reality, Our Unwavering Commitment Always

- Innovative Design Solutions

- Efficient Project Management

- Skilled and Experienced Team

- Premium support 24/7